In industrial production, cold chain logistics, outdoor engineering, and other scenarios, motors often operate in environments below -10°C, with extreme conditions dropping as low as -40°C. Low temperatures exert multiple adverse effects on the motor’s insulation system, lubrication performance, mechanical structure, and electromagnetic characteristics. Mild impacts include difficulty starting and reduced efficiency, while severe cases may lead to winding short circuits, bearing seizure, and other failures that disrupt production continuity. Starting from the mechanisms by which low temperatures affect motors, this article presents a comprehensive stability assurance plan covering material selection, structural optimization, and operational maintenance, helping equipment run reliably and durably under low-temperature conditions.

I. Core Hazards of Low-Temperature Environments on Motor Operation

Low temperatures do not affect motors through a single factor; instead, they trigger chain reactions across four systems—insulation, lubrication, mechanics, and electromagnetism—via physical interactions. Understanding this is fundamental to ensuring stable motor operation.

Embrittlement and Failure of Insulation Systems: Increased Short-Circuit Risk

Insulation materials such as winding varnish and insulating paper transition from flexible to brittle states at low temperatures. Ordinary insulating paper experiences a 30% or more drop in tensile strength at -20°C, making it prone to cracking and varnish peeling during startup vibrations, which significantly reduces insulation resistance. Additionally, moisture inside the insulation condenses into ice crystals at low temperatures, disrupting its uniformity. At -30°C, the dielectric loss reaches 2–3 times that at room temperature, and breakdown voltage decreases by 15%–20%. Prolonged operation can easily cause interphase or ground short circuits in windings. Repeated low-temperature start-stop cycles accelerate microcrack propagation in insulation materials, reducing their lifespan to 60%–70% of that in normal-temperature environments.

Lubrication System Failure: Surge in Mechanical Resistance

Ordinary lithium-based grease rapidly solidifies below -20°C, with viscosity increasing over 10 times compared to room temperature. This leads to lubrication failure between bearing rolling elements and inner/outer rings, causing a sharp rise in friction resistance. During operation, abnormal noise exceeding 85 dB is generated, and excessive bearing temperature rise accelerates raceway wear and rolling element fracture, ultimately seizing the motor. Meanwhile, metal components contract at low temperatures, turning interference fits between shafts and bearings into clearance fits, resulting in shaft displacement and uneven air gaps, which exacerbate vibration and losses.

Attenuation of Electromagnetic Performance: Dual Decline in Startup and Efficiency

The permeability of silicon steel sheets in the motor core decreases with falling temperatures. At -30°C, ordinary silicon steel sheets see a 20% reduction in permeability, leading to a 25%–30% increase in excitation current and a drop in power factor from 0.85 (room temperature) to 0.7–0.75. Output efficiency declines, and reactive power loss in the grid increases. Critically, low temperatures reduce starting torque to only 65%–70% of that at room temperature. Combined with increased lubrication resistance, this makes startup failure or overheating/burning of windings during startup highly likely.

Damage to Mechanical Structures and Seals: Accelerated Deterioration from Foreign Intrusion

Ordinary steel plate casings exhibit low-temperature brittleness at extreme lows like -40°C, with impact resistance plummeting and susceptibility to cracking under external force. Sealing rubber strips harden and shrink, reducing protective performance and allowing external moisture and dust to enter the motor, accelerating conductor corrosion and insulation degradation. Low-temperature contraction of metal components also causes abnormal fit clearances, leading to rotor displacement, stator-rotor friction, and other serious faults.

II. Source Control: Selection and Structural Optimization of Low-Temperature-Adapted Motors

To ensure stable motor operation in low temperatures, the first step is to address material and performance shortcomings through targeted selection and structural design, thereby reducing failure risks at the source.

Material Upgrades: Core Choices for Low-Temperature Adaptation

For insulation materials, prioritize those with excellent low-temperature toughness: replace winding varnish with low-temperature-modified epoxy resin varnish (glass transition temperature as low as -40°C) and use polyimide film composite paper for insulating paper, which retains good flexibility even at -60°C. Vacuum impregnation should be applied to windings to minimize internal voids and prevent moisture condensation. For casings and end covers, select low-temperature-tough steels such as Q355ND and Q345D, with impact energy ≥34J at -40°C to avoid brittle fracture. Fasteners should use low-temperature-resistant high-strength bolts. Sealing rubber strips should be silicone rubber, suitable for a wide temperature range of -60°C to 200°C, ensuring reliable sealing.

Optimization of Lubrication and Mechanical Structures to Reduce Low-Temperature Resistance

Use sealed deep-groove ball bearings to prevent grease leakage. Replace lubricants with low-temperature-specific types, such as polyurea-based grease (applicable for -40°C to 120°C) and polyalphaolefin (PAO) synthetic oil (pour point below -60°C). Fill the bearings with 10%–15% more lubricant than at room temperature to ensure fluidity in low temperatures. For shaft-to-bearing fit clearances, implement low-temperature compensation: increase the room-temperature interference by 0.01–0.02 mm to offset gap formation due to low-temperature contraction, preventing shaft displacement.

Electromagnetic System Adaptation to Enhance Low-Temperature Startup and Efficiency

Select 35W250 silicon steel sheets, which have minimal permeability attenuation at low temperatures, or attach glass wool thermal insulation layers to the core surface to reduce the impact of temperature fluctuations. Apply polytetrafluoroethylene (PTFE) low-temperature anti-condensation coating to conductor surfaces to prevent moisture adhesion and conductive path formation, avoiding abnormal copper loss. For high-power motors, install an independent forced-air cooling system with a closed duct to control temperature, preventing performance fluctuations caused by low temperatures and uneven heating.

Upgraded Protection Levels to Resist Moisture and Dust

Low-temperature environments are often accompanied by high humidity, so the motor’s protection level should be no lower than IP55, with IP66/IP67 preferred for high-humidity conditions to prevent water and dust ingress. Add waterproof sealing gaskets to key areas such as junction boxes and bearing end covers, and design drain holes in the base to avoid water accumulation and corrosion.

III. Operational Maintenance: Refined Practices to Fortify Stability

After optimizing selection, scientific operation and maintenance are critical to long-term motor stability, focusing on three core aspects: preheating, moisture prevention, and inspection.

Preheating Before Startup to Avoid Cold-Start Damage

Directly starting motors in low-temperature environments is strictly prohibited. Instead, preheat the windings and bearing end covers using external PTC heaters or space heaters, raising the internal temperature to 5°C–10°C within 15–30 minutes before startup. This effectively prevents insulation embrittlement and insufficient starting torque. When the motor is idle, keep the heater running at low power to prevent internal condensation, especially in high-humidity, low-temperature environments, where a dehumidifier should be activated if humidity exceeds 75% (monitored via a humidity sensor).

Regular Inspection and Maintenance to Identify Hidden Risks Promptly

Check the lubrication system every 3 months: if the grease solidifies or degrades, replace it immediately to avoid lubrication failure. Test insulation resistance monthly; if values drop, dry the motor promptly to prevent short circuits. Regularly inspect the casing and seals for cracks or aging, replacing damaged parts to maintain protection. Monitor operational parameters in real time, paying close attention to starting current, temperature rise, and vibration values, and shut down for inspection if abnormalities occur.

Environmental Adaptations to Improve Operating Conditions

Install thermal insulation covers on the motor casing to reduce the impact of low ambient temperatures on internal temperature. Position the motor in a well-ventilated, dry area, away from direct exposure to water or wind/snow. If unavoidable, add splash guards and windshields. In high-humidity, low-temperature settings, place dehumidifiers around the motor to lower environmental humidity and reduce external condensation risks. For frequently started/stopped motors, adjust the start-stop interval reasonably to minimize thermal cycling damage to insulation materials.

IV. Additional Requirements for Explosion-Proof Motors in Special Conditions

In explosion-proof scenarios such as chemical plants and mines, low-temperature-operating explosion-proof motors must additionally ensure explosion-proof performance to avoid compromising the flameproof structure. First, adopt a combined flameproof + increased safety (Ex d + Ex e) structure, with increased safety insulation liners added inside the flameproof chamber for dual protection. Second, adjust electrical clearances based on altitude: at 2,000 meters above sea level, clearances should be 15% larger than the original design. Third, apply low-temperature-specific anti-rust grease to flameproof surfaces to prevent low-temperature rusting, which could impair flameproof performance.

Stable operation of motors in low-temperature environments hinges on “source adaptation + process control.” By selecting low-temperature-specific materials and optimizing structures to address inherent weaknesses, and then implementing preheating, regular maintenance, and environmental modifications for ongoing protection, the hazards of low temperatures to insulation, lubrication, mechanical, and electromagnetic systems can be effectively mitigated. Whether for conventional industrial motors or explosion-proof variants, adhering to these strategies ensures efficient, reliable, and long-term operation in low-temperature conditions, safeguarding production operations.

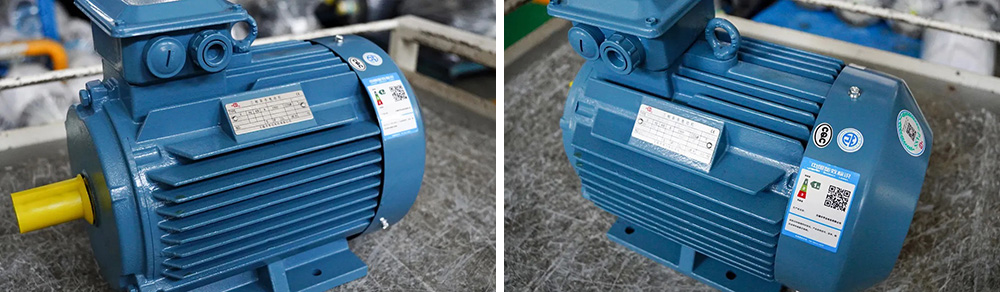

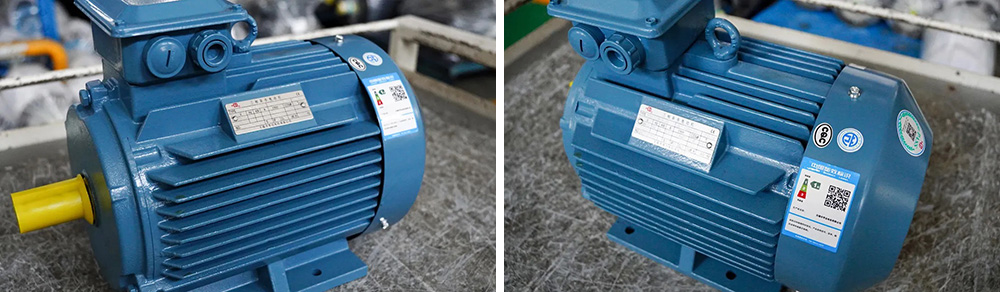

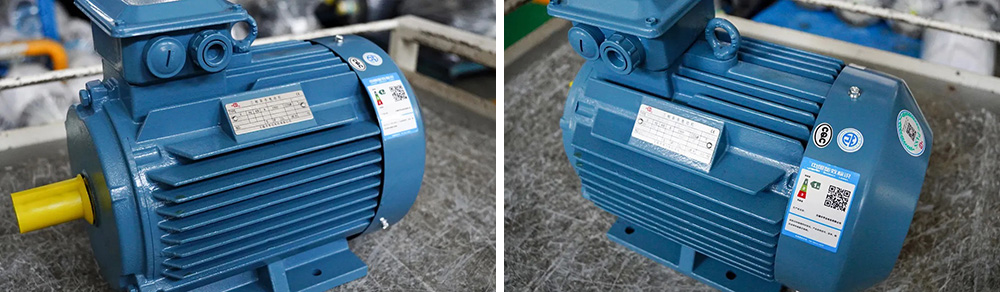

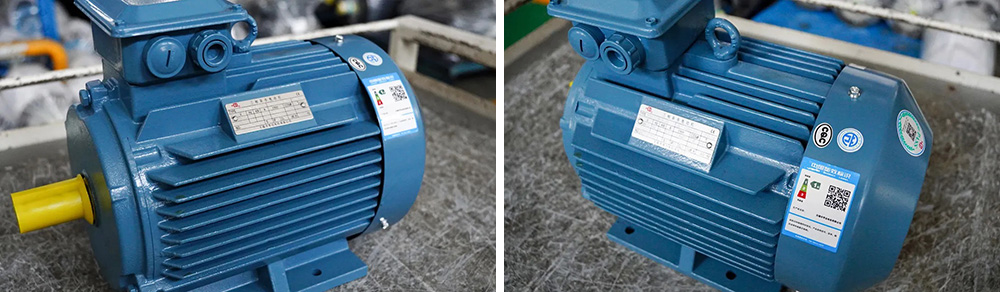

Hengda Motor has long specialized in the R&D, production, and service of various motors. With advanced technology and equipment, lean manufacturing processes, reliable product quality, and satisfactory after-sales service, we provide customers with the most suitable professional motor solutions, creating greater social value.